|

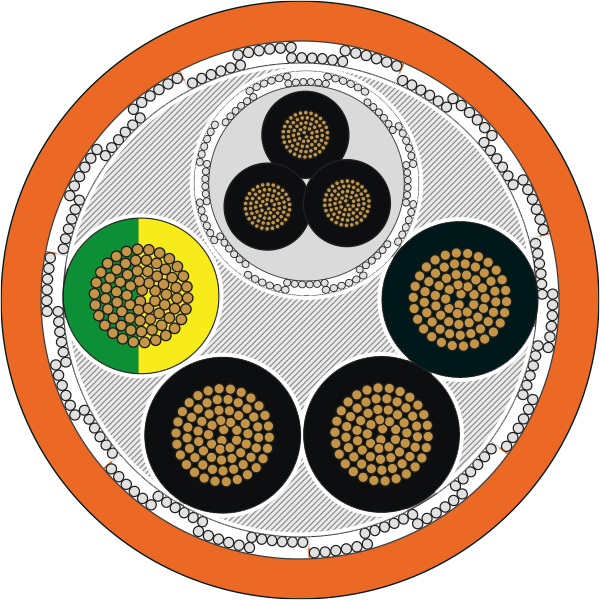

DRIVEConn® MT - SERVOSERVO eq. SEW® |

BP PVC 0.6 / 1.0 kV |

Basic Performance |

Cables conforming to SEW® standard, designed for power and control actuator drive systems. Highly flexible conductors, PVC-resistant PVC or PUR outer sheath provide a suitable product for a wide range of high-performance,ranging from fixed applications to high speed drag-chains. High dynamic parameters, reduced bending radii, chemical resistance to oils and industrial fluids. The PUR sheath version is also suitable for low temperature applications. Low dielectric capacity, shielded high-tinned copper braid for high EMC protection and a Sew® standard construction. The cables are UL / CSA and EAC approved and follow the DESINA standard. Note: The reported SEW codes are trademarks of SEW Eurodrive and are for comparative purposes only. Desina® is a registered trademark of the German machine tool builders (VDW). The article codes refer to existing MotionCables products. The drawings are not on a scale and do not represent a detailed picture of the products to which they refer. |

CONSTRUCTION FEATURES

|

PRODUCT'S FEATURES

|

MECHANICAL FEATURES

|

| MotionCables Code | OEM Code | Formation | Outer Diameter | Copper Weight | Outer Sheath |

|---|---|---|---|---|---|

| SFSS15G07UR-A | [4G1,5+(3x1,0)] | 11.8 | 150.0 | RAL 2003 Orange PVC TM5 | |

| SFSS13G07UR-A | [4G2,5+(3x1,0)] | 13.4 | 213.0 | RAL 2003 Orange PVC TM5 | |

| SFSS11G07UR-A | [4G4+(3x1,0)] | 15.0 | 280.0 | RAL 2003 Orange PVC TM5 | |

| SFSS09G07UR-A | [4G6+(3x1,5)] | 17.0 | 390.0 | RAL 2003 Orange PVC TM5 | |

| SFSS07G07UR-A | [4G10+(3x1,5)] | 20.0 | 620.0 | RAL 2003 Orange PVC TM5 | |

| Note The data reported here are not binding and may be changed based on technical choices, modifications and/or improvements the manufacturer deems necessary. Reference to trademarks and standards is made for reference or information purposes only. These trademarks and standards are the exclusive property of their respective owners. |

|||||